Electrical Panel Phenolic Labels Things To Know Before You Buy

Wiki Article

What Does Electrical Panel Phenolic Labels Do?

Table of ContentsThe Ultimate Guide To Electrical Panel Phenolic LabelsThings about Electrical Panel Phenolic LabelsThings about Electrical Panel Phenolic LabelsElectrical Panel Phenolic Labels - An Overview

From: buck [# 6] 6 May 2005 Thanks for the input every person. I guess the important things I really did not account for was just how quickly the cutters will boring. It's difficult to think that you can just get about 20 tags from a bit prior to needing to transform it. Shouldn't carbide last longer? I will offer Capability Plastics a telephone call to obtain a quote on the cutting of the blanks for me.We pay the individuals about 20c a broken drill (the drill section is virtually needle slim, breaks quickly) and we stroll away with at least 2000 of them - some are 6mm (near 1/4") in size, With a cutter mill you are in control and can make the right cutter for the ideal product and do a lot more besides.

When we sent cutters out for developing, they came back with mixed results. Pointer dimensions were often inconsistent and some of the smaller sized idea widths really did not execute well. That had not been helping me, so the really initial piece of devices I bought, was a used New Hermes cutter mill (CG-4).

Having specifically the cutter you require, when you need it? Invaluable:--RRB- BTW - I when stumbled upon a shop that claimed they make so much money on rotating engraving, they don't have their cutters resharpened. They simply get brand-new. Ooof! I simply desire I can bear in mind which shop that was.

Electrical Panel Phenolic Labels Can Be Fun For Anyone

You send out in a first-time-sharpened cutter and return a brief stub (Electrical Panel Phenolic Labels). There are some business that have a history of returning sharp cutters that are the asked for suggestion size, yet not the initial cutter that was sent out to be sharpened. What I have discovered to do is send this supplier my stubs in hopes of obtaining some added length as a result of the swapPrimarily in my component of the globe, contractors wont accept anything disallowing phenolics cos they attempted and examined and so on. 9 May 2005 Same here - if the specs call for phenolic, we have to use phenolic, no matter how much we want we could substitute Romark instead.

Cindy MFrom: Jim (PUZZLEHEAD) [# 15] 9 May 2005To: Cindy (CINDYM) [# 14] 9 May 2005 There are absolutely applications where phenolic is the far better item. I have actually located the bulk of the time when "penolic" is specified, they only asked for phenolic due to the fact that they thought it was a generic term for the little engraved find plastic tags.

Getting The Electrical Panel Phenolic Labels To Work

Jim, From: Cindy (CINDYM) [# 16] 9 May 2005To: Jim (PUZZLEHEAD) [# 15] 9 May 2005 I hear what you are stating, and when we can we do relocate clients to the non-phenolic products. Numerous are uneducated, and that is our job - to let them recognize they have alternatives. It seems that nearly all, if not all, our federal government agreements need phenolic - the specs actually mean it out, so there isn't much I can do regarding transforming them over if that is what the specifications request.

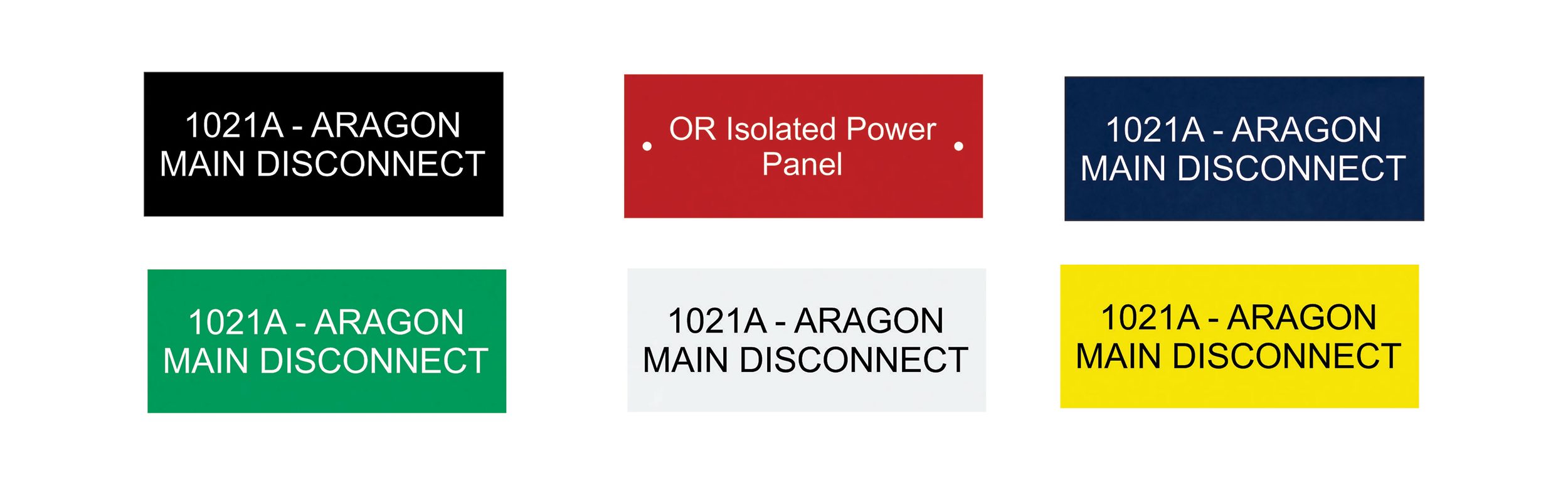

Phenolic is a non-conductive material (Lamicoid) that is excellent to utilize for creating phenolic tags and tags for the electrical market. The phenolic tags have good qualities such as resistance to abrasion, heat, and chemicals. Phenolic plates work as electrical insulators. Such labels are resilient and have lasting toughness the original source as well.

As a result of such factors, Engraved labels have located excellent choices to utilize for establishing electrical things such as: In instance, you need a label for the electric button, you must like phenolic plates switches - Electrical Panel Phenolic Labels. These are trusted and risk-free options for electric changing needs in markets. The phenolic buttons are long lasting and have reduced upkeep too.:: Due to electrical insulation residential properties, phenolic tags or tags are likewise considered for electrical panels

Some Ideas on Electrical Panel Phenolic Labels You Should Know

In a lot of sectors, phenolic plastics have an application to construct device signage as a result of their resonance resistance. Due to such factors, several electric machines do consist of phenolic tags to reduce their excessive vibration. Phenolic Plates and labels are also ideal to use as a result of their corrosion-resistant building. On contrary, the steel labels are incomplete for this reason.

We engrave many of these, we just bill a level rate cost of $ 1. 85, regardless of the number of personalities or lines of message. Amount discounts normally apply. 3). What material are Kentron's nameplates made from? Back in the past days (prior to the '80's or thereabouts) nameplates for the electrical professions were largely made from "Micarta".

There is a broad selection of this material to choose from that has actually been specially developed to achieve superior outcomes making use of laser technologies. Yes, the production inscribing product we use is UV stable and suitable for indoor/outdoor applications.

Report this wiki page