Some Known Questions About Injection Mold.

Wiki Article

See This Report about Injection Mold

Table of ContentsOur Injection Mold PDFsOur Injection Mold IdeasEverything about Injection MoldWhat Does Injection Mold Do?Unknown Facts About Injection MoldA Biased View of Injection Mold

Celebrity Rapid is completely certified to the high quality management system of ISO 13485 for medical devices. When you prepare to start your next medical product, contact us for a complimentary design for making testimonial and quotation - Injection Mold. We can ensure you utilize the appropriate materials and also the ideal procedure that finest fits your medical tool requirements.Before ejection from the mold, shot formed components are cooled off from manufacturing temperature levels to ensure that they hold their shape when expelled. During the component cooling action of the molding procedure, changes in stress, velocity and also plastic viscosity need to be minimized to avoid defects. Few facets are much more important throughout this duration than wall surface density.

Picking the proper wall surface density for your part can have drastic results on the expense and also manufacturing speed of production. While there are no wall surface density limitations, the goal is normally to choose the thinnest wall feasible. Thinner walls use less product which minimizes expense and also take less time to cool, reducing cycle time.

How Injection Mold can Save You Time, Stress, and Money.

Density changes ought to be made slowly, like 3 to 1. This steady transition avoids stress focus and also sudden cooling distinctions.

What Does Injection Mold Mean?

When it comes to making your parts, you have a major decision to make. Should you make your components making use of plastic shot molding or light weight aluminum pass away spreading!.?.!? To help you choose, let's take a look at the major advantages and also disadvantages of each. The procedure of making a component is generally the exact same whether you are utilizing die casting or shot molding.You then liquify the material and make use of severe pressure to inject it right into the die/mold. You then cool the die/mold with inner air conditioning lines as well as die spray on the die dental caries. You open up the die as well as remove the shot. Although there are some variants in method, the major distinction in between die casting and shot molding is that pass away casting makes use of some type of metal, often a light weight aluminum alloy, as the raw product, while shot molding utilizes plastic or polymers.

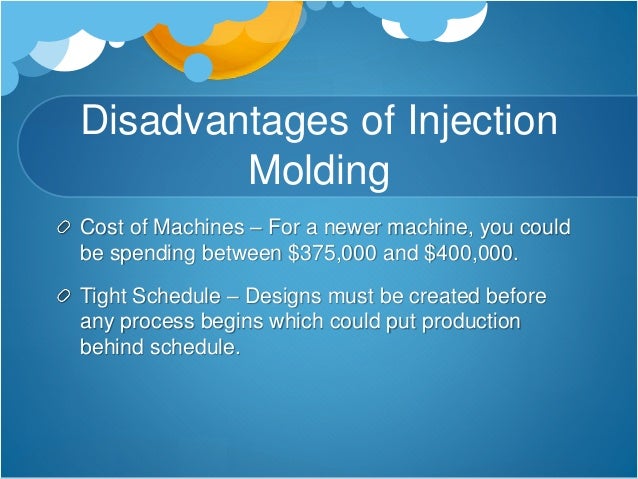

Manufacturing is quicker due to extra adaptability in the molding procedure Plastic Shot mold and mildews can fit have a peek here different plastic or polymer materials Fillers can be used in plastic mold and mildews to raise toughness Effective process with very exact finishes Reliable procedure with a high degree of accuracy No need for secondary procedures Challenging styles can be much more easily cast Produces higher-quality items with much better tolerance that will last longer So why would certainly you pick injection molding over die casting? If you are looking to generate a whole lot of parts very reasonably, shot molding might be the means to go, as labor and also material costs are rather light, although it is crucial to keep in mind that the price of the plastic injection molding machines themselves and also any type of secondary tools can be relatively expensive.

Fascination About Injection Mold

Even if you are creating less complex parts, many individuals favor the evident sensation of sturdiness and also top quality you enter a strong steel component over a plastic part. As soon as you have determined that aluminum pass away spreading is the way to choose all your component manufacture needs, the next step is to speak to Premier Engineered Products.Companies that know die casting call Premier Engineered Products. At Premier Engineered Products, we are dedicated to helping you provide a better product to your customers by providing you fantastic service and exemplary quality his explanation every time you place an order with us.

To discover how we can put our high-tech metalworking machines and also proficiency to help you now, simply call us online today.

The Definitive Guide for Injection Mold

At Abtec Inc., we're honored to provide personalized mold making services, assisting customers bring their product visions to life. Functional and trustworthy, plastic injection molding is made use of to develop a massive variety of day-to-day products. One of one of the most prominent techniques for mass producing plastic components, this strategy proceeds to rise in appeal across varied industries and also applications.Considering that durations between cycles can be as brief as 15 seconds, even more parts can be made suggesting countless accuracy parts can be generated per hour, relying on the particular mold and mildew. This high production output price helps firms increase profits and earnings margins. Customized plastic shot molding enables great style adaptability.

005 inch. Having a full understanding of consumers' requirements is essential for making certain appropriate item form and also feature. With years of sector experience as well as a dedication browse around these guys to close customer partnership, our team has the ability to determine the suitable layout as well as material for clients' tasks, as well as can start work swiftly on models (Injection Mold).

Little Known Facts About Injection Mold.

Material choice is a vital step in the production process, and also have to be based on the designated stamina of completion item. Other key elements to bear in mind consist of appearance attributes, such as shade and also surface, and also any applicable regulative requirements. Loads of material alternatives are readily available to satisfy details application requirements.

Report this wiki page